CALTECH ENGINEERING SERVICES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to CALTECH ENGINEERING SERVICES

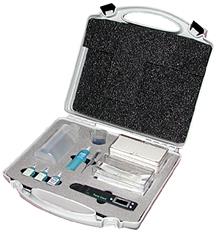

Bent Beam Test

Caltech Engineering Services India manufacture and supply stress corrosion cracking bent-beam testing instument to accurately determine the resistance to sulfide stress corrosion cracking (SSC) as per NACE TM0177 Standard Method B and ISO 7539. We also supply defection device for measuring accurately deflection achieved by bending. NACE TM0177 describes Laboratory Testing of Metals for Resistance to Sulfide Stress Cracking and Stress Corrosion Cracking in H2S Environments

NACE TM 0177 Method B, the NACE Standard Bent-Beam Test, provides for testing carbon and low-alloy steels subjected to tensile stress to evaluate resistance to cracking failure in low-pH aqueous environments containing H2S. The compact size of the bent- beam test specimen facilitates testing small, localized areas and thin materials. Bent beam test specimens loaded to a particular deflection give a failure/no-failure test result. We recommend to use this test for thin material thickness or low diameter pipe materials and welding test. This method involves deflecting each test specimen in a series by applying a bending stress. The stressed test specimens then are exposed to the test environment, and the failure (or no-failure) by cracking is determined hence becoming very popular and easy test method for labs. There is also benifit in the method which constitutes a constant- deflection test of low test specimen compliance. The computed stress is called a pseudo-stress because it does not reflect. At a time 12 to 16 samples can be tested.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.